Precision under pressure

Norse Cutting provides services such as water cutting, diamond wire cutting, cold cutting, bolt preloading, hot tapping, decommissioning and mechanical machining – with a focus on safety, efficiency and customized solutions.

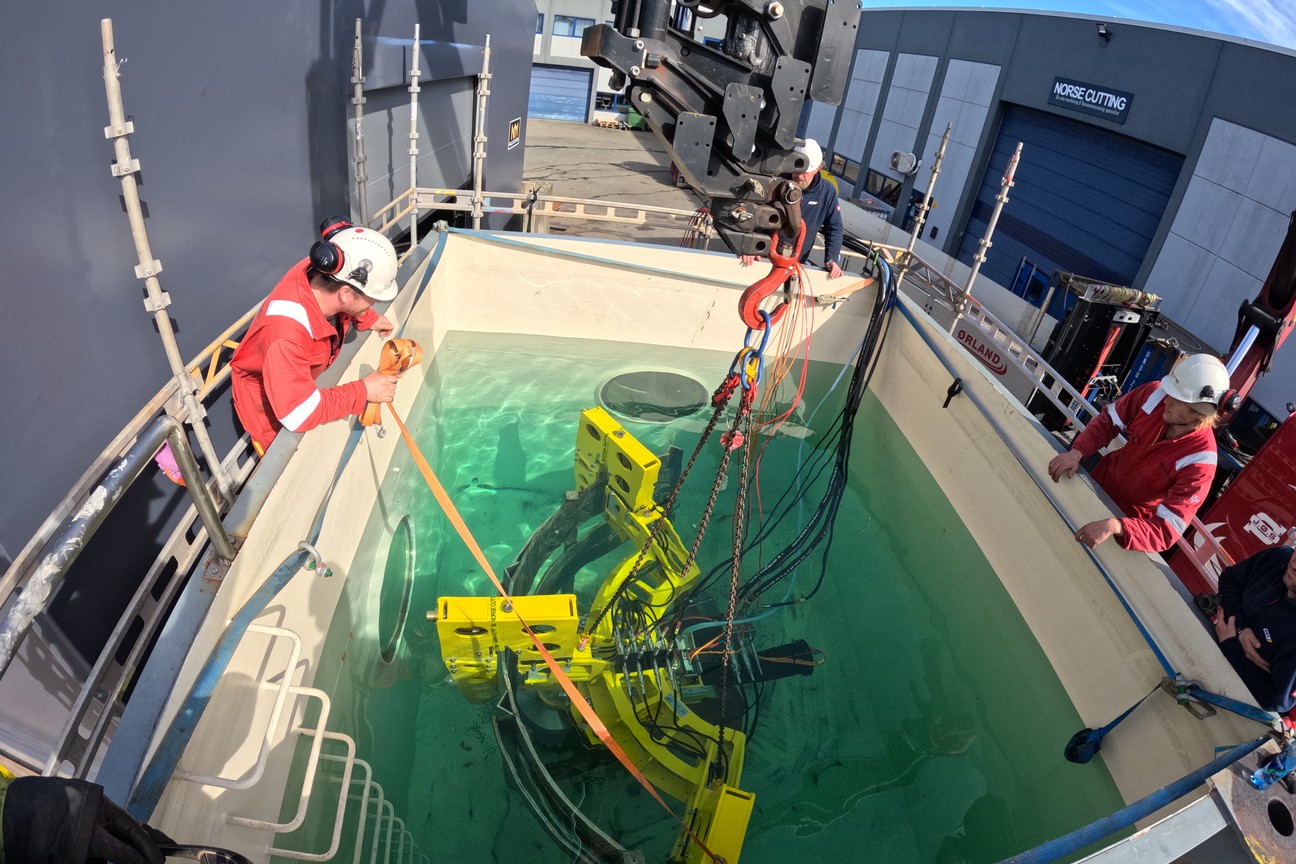

In this project, Norse Cutting has developed a special tool for subsea cutting, but with a completely unique approach: the operation takes place indoors, in shallow water – about 30 meters deep – inside the cooling system of a nuclear power plant. This places high demands on precision, safety and adaptation, and Norse Cutting's ability to combine subsea technology with engineering in demanding environments is clearly expressed.

Through innovation and close collaboration with the customer, Norse Cutting has delivered tools that not only meet technical requirements but also allow for reuse and efficient operation in future projects. This is yet another example of how the company brings together experience and innovation to solve complex challenges – wherever they arise.

Three Tools – One Delivery: Cutting Systems for Nuclear Decommissioning

From 2023 to 2025, our engineering team designed and built three advanced cutting tools, two with dual configurations, for decommissioning of several specific structures inside a nuclear facility’s cooling pool. The delivery contained innovative mechanics, combining electric drive and hydraulic actuation,all controlled through a specially designed controlled system developed by our client. Delivering a safe, precise, and compliant cutting capability in a demanding environment.

Test phase, from idea to basic design

The customer contacted Norse Cutting in 2023, to explore cost-saving methods for the underwater demolition.

An important aspect of the delivery was strict requirements for the handling and storage of consumables, all items involved needed to be reviewed considering required cleaning, storage and contamination hazard.

-The customer designed test pieces and proposed cutting methods, while Norse Cutting provided knowledge, equipment and premises.

-Our engineers proposed their own solutions and produced test pieces.

-Several cutting methods were tried and documented. One test piece proved particularly demanding – here we went from diamond wire cutting to diamond blade in close collaboration with the customer.

The assignment required tools that could operate fully submerged and deliver consistent performance on large stainless-steel structures.

The Design Phase – Complexity in the Nuclear Power Environment

The project grew into a family of three machines with multiple configurations, built on common components to reduce costs and increase reuse. The tools had the following features:

2- and 3-axis electric control for high precision.

Hydraulic clamping and saw blade operation for high power output.

Our focus was to optimize the design to require fewer resources, resulting in both cost savings and more efficient execution. In addition, the number of components was reduced, resulting in lower inventory needs and increased possibilities for reuse in future projects.

There were strict requirements for the design related to:

-Corrosion-resistant materials and surface treatment.

-Decontamination, painting and cleanability.

-Smart solutions for blade change in the middle of the cut without losing position.

Throughout the whole design phase, regular design-review meetings were held with the client to ensure that all requirements were taken care of. The overall project contained over 400 drawings and 4000 items

From design to Production

Production of the tools was approved in 2024 and began in August 2024. The tools were ready for FAT by spring 2025.

The test phase, both the IAT and the FAT, was long. The test criteria demanded very thorough testing. A couple of adjustments, some small and some larger, were needed. One of the biggest challenges we discovered during this phase was related to maintaining and protectingthe surface treatment, when changing from one configuration to another.